Engineering Solutions

ICE supports its clients with specialised engineering services. We have participated in International Oil and Gas projects, both greenfield and brownfield. ICE together with its partners delivers state of the art engineering solutions to cover the following project stages:

– PRE FEED

– FEED

– Basic Engineering

– Detailed Engineering

Some specific deliverables and specialized services are as follows:

Process Engineering

- Basis of Design

- Process Description Reports

- Heat and Material Balance

- Process Simulation

- Process Flow Diagrams

- Piping and Instrumentation Diagrams

- Cause and Effect Diagrams

- Equipment sizing calculations

- Process Datasheets

Materials and Corrosion Engineering

- Materials Selection Philosophy Reports

- Materials Selection Guides

- Corrosion Control Documents

- Corrosion Monitoring Drawings

- Coatings Specifications

- Insulation Specifications

- Risk Based Inspection Exercises

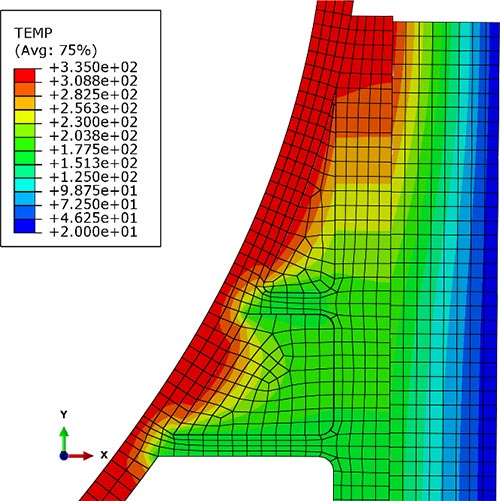

- Remnant Life Assessments

- Fitness for Service Studies

- Cathodic Protection Engineering

- Pipelines Assets Integrity Studies

Loss Prevention

- Fire Protection Design Basis

- Fire and Gas Detection and Mapping

- Fire Water Network Layout

- Fire Water System P&ID’s and Hydraulic Calculation

- Fire Zone Layouts

- Hazardous Area Classification Layouts

- Fire Alarm Cause and Effects

- Safety Studies

- HAZOP, HAZID and SIL Studies

- QRAs

Piping Engineering

- Piping Material Specifications.

- Piping bulk material estimation.

- Material Requisitions, Technical bid evaluation & Vendor drawing review.

- Pipe Stress analysis (Dynamic & Static)

- Piping design specifications

- Piping Supports Design

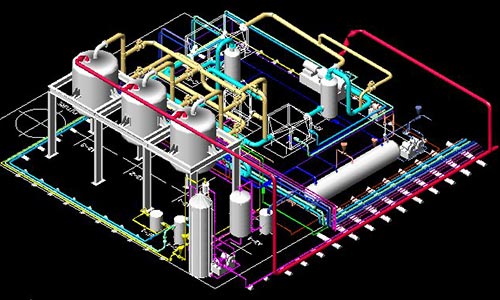

- 3D Modelling

- Plant / Piping Layouts & isometrics extraction from 3D models.

- Post Detail Engineering, Field engineering support and construction assistance.

- Pipe wall thickness calculations as per ASME B31.1, ASME B31.3, ASME B31.4 & ASME B 31.8

- Pipelines full engineering spectrum inclusive of pipelines stress analysis and alignment sheets

- Piping Systems Materials Requisitions

Civil Engineering

- Structural Design- AISC, BS, EURO, & API codes

- Developing Design criteria, Specifications and Standard drawings

- Structural GA Drawings & MTO

- Structural Fabrication drawings

- Foundation Design or Reaction forces on foundations

- 3D Modelling

- Lifting, Transportation, Seismic, Wind, Fatigue, Vibration and In-place analysis reports for Modular constructions

Electrical Engineering

- Electrical Bulk MTO

- Earthing Systems Designs

- Electrical Material Requisitions

- Preparation of Datasheets and Material Requisitions

- Single line diagrams

- Electrical layouts (Lighting / Cable routing / Earthing)

- Schematics and wiring / interconnection wiring diagrams

- 3D Modelling

Mechanical Engineering

- Mechanical Equipment Data Sheets (inclusive of static and machinery)

- Rotating Equipment Specs

- Static Equipment Specs

- Rotating and Static Equipment Material Requisition

- Technical Bid Evaluation (based on both CAPEX vs OPEX for Rotating Equipment)

- Static equipment Fabrication Drawings.

Instruments and Control

- I&Cs Bulk MTO

- Specification for Field and Online instruments

- DCS, PLC, ESD Engineering

- Preparation of Datasheets and Material Requisitions

- Cable Tray Layouts

- 3D Modelling of Instrument, Junction box, Cable trays etc.

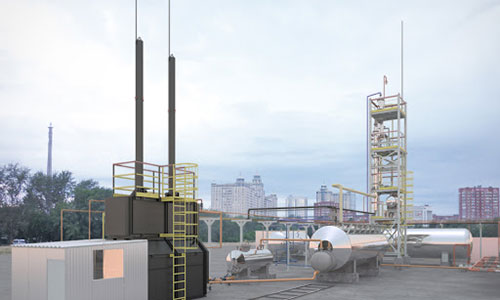

NPC, Condensate Distillation Unit

ICE Scope included Basic and Detailed Engineering for the following Engineering deliverables:

- Piping Scope inclusive of 3D Modelling

- Materials and Corrosion Scope inclusive of Materials Selection Report and Diagrams

- Risk Based Inspection Program

- Loss Prevention Engineering Scope

- Fired Heaters Equipment Engineering Scope

- Cooling Water Feasibility Study

- Cathodic Protection Engineering Design

- Coatings, Insulation and Fireproofing Engineering Scope

In addition to supporting the EPC contractor with a multidisciplinary team in all specialties as follows:

- Process Engineering

- Loss Prevention Engineers

- Piping Engineers

- Instruments and Control Engineers

- Civil Engineers

- Electrical Engineers

- Document Controllers

- Project Management

- Project Control Engineers

Total seconded manpower is 90 engineers of different levels of expertise

Key Engineering References

NPC, Condensate Distillation Unit

ICE Scope included Basic and Detailed Engineering for the following Engineering deliverables

- Piping Scope inclusive of 3D Modelling

- Materials and Corrosion Scope inclusive of Materials Selection Report and Diagrams

- Risk Based Inspection Program

- Loss Prevention Engineering Scope

- Fired Heaters Equipment Engineering Scope

- Cooling Water Feasibility Study

- Cathodic Protection Engineering Design

- Coatings, Insulation and Fireproofing Engineering Scope

In addition to supporting the EPC contractor with a multidisciplinary team in all specialties as follows

- Process Engineering

- Loss Prevention Engineers

- Piping Engineers

- Instruments and Control Engineers

- Civil Engineers

- Electrical Engineers

- Document Controllers

- Project Management

- Project Control Engineers

Total seconded manpower is 90 engineers of different levels of expertise

Engineering scope included the Materials and Corrosion Engineering Deliverables. In addition to secondment of Process, Loss Prevention, Piping and Planning Engineers to work at the EPC contractor offices

Fitness for Service for Static Equipment

Dana Gas ZORA Field Materials Selection